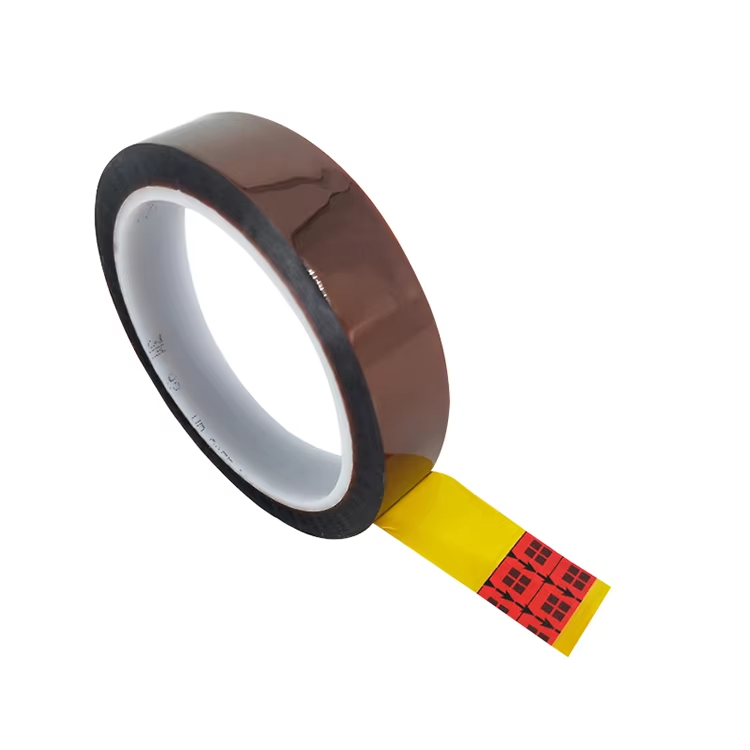

3M™ Polyimide Film Electrical Tape 92

Highly conformable with a pressure-sensitive, acrylic adhesive

Flame-retardant and has polyamide backing

Suitable for use as wave solder masking tape in a printed circuit board assembly

Description

Related Products

3M-33+

3M™ VHB™ Tape 5962

3M 3903

Innovative Highlights

3M™ Tape 92: Unleashing High-Performance Electrical Innovation

The 3M™ Tape 92 is not just any electrical tape; it's a marvel of engineering with a polyimide film backing that provides robust insulation for coils, harnesses, and capacitors. This flame-retardant wonder can endure temperatures from 0°C to 180°C (32 to 356 °F), making it a reliable choice for a wide range of applications.

Smooth and Secure: The 3M™ Polyimide Film Electrical Tape 92

As a solder masking tape in printed circuit board assembly, the 3M™ Polyimide Film Electrical Tape 92 stands out with its smooth and uniform thermosetting silicone adhesive coating. This innovative feature ensures excellent adherence while eliminating bare spots and lumps, providing a clean and professional finish. Plus, it's UL Listed and RoHS 2011/65/EU Compliant, so you can trust its quality and safety.

By adding a touch of creativity and emphasizing the unique features and benefits of the product, the content becomes more engaging and appealing to readers.

Typical properties

Details

Adhesive Material

Silicone, Thermosetting Silicone

Adhesive Type

Silicone

Application

Insulation

Backing (Carrier) Material

Polyimide Film

Backing (Carrier) Thickness (Metric)

0.025 mm, 1 mm

Dielectric Strength

7500 V

Electrolytic Corrosion Factor

1

Elongation at Break

55 Percent

Insulation Resistance

1 x 10^6 megohms, > 10^6 megohms

Maximum Operating Temperature (Celsius)

180 ℃

Maximum Operating Temperature (Fahrenheit)

356 ℉

Minimum Operating Temperature (Celsius)

-40 ℃, 0 ℃

Product Color

Amber

Shelf Life

5 Year

Specifications Met

RoHS 2011/65/EU, UL 510, UL Listed, UL Recognized

Tensile Strength (Metric)

53 N/cm

Total Tape Thickness without Liner (Imperial)

2.75 mil

Total Tape Thickness without Liner (Metric)

0.07 mm

eClass 14 Classification Group

27140708

Dimensions and Classifications

Overall Length (Imperial)

36 yd

Overall Length (Metric)

33 m

Overall Width (Imperial)

0.25 in, 0.375 in, 0.5 in, 0.681 in, 0.75 in, 0.875 in, 1 in, 1.33 in, 1.75 in, 2 in, 3 in, 12 in, 12.5 in, 15.5 in, 25 in

Overall Width (Metric)

6.35 mm, 9.525 mm, 12 mm, 12.7 mm, 17.2974 mm, 19.05 mm, 22.225 mm, 25.4 mm, 33.782 mm, 44.45 mm, 50.8 mm, 76.2 mm, 304.8 mm, 317.5 mm, 584.2 mm, 635 mm