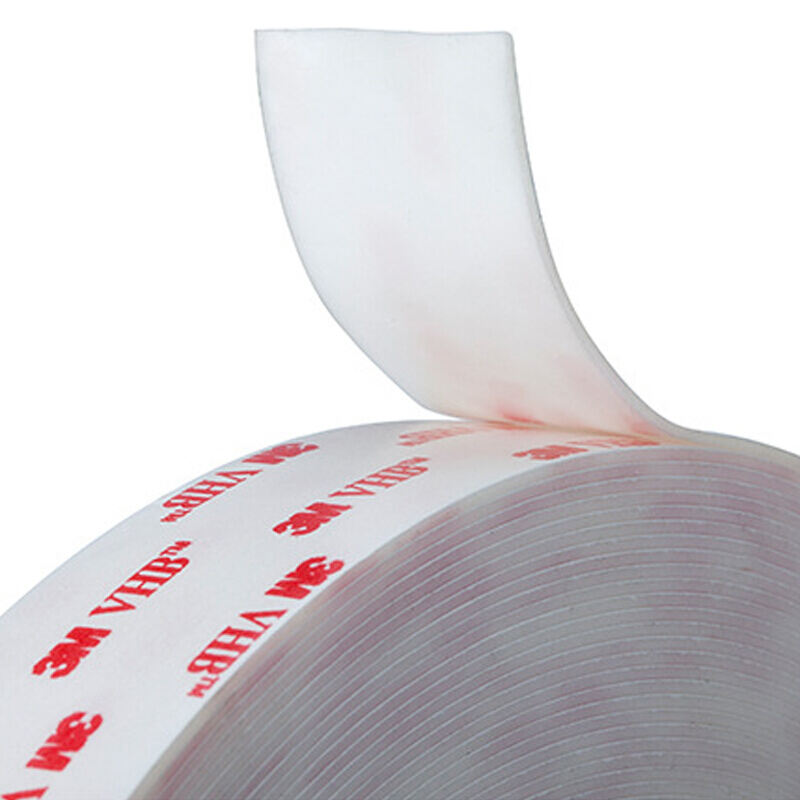

3M™ VHB™ Tape 4950

LONG-TERM DURABILITY: Offers a fast and easy-to-use all-acrylic bonding method that gives immediate handling strength — no need to fixture or wait for a cure

SMOOTH AND SEAMLESS: With a thickness of 45 mil (1.1 mm), this tape is designed as an alternative to mechanical fasteners, such as rivets, welds, and screws, or liquid adhesives

BUILT TO PERFORM: Delivers high shear strength and reliable surface adhesion due to an acrylic foam core and general-purpose adhesive

Description

Related Products

3M-33+

3M™ VHB™ Tape 4951

3M™ VHB™ Tape 5962

3M™ VHB™ Tape 4950 is a double-sided tape comprised of a general-purpose acrylic adhesive with a firm, foam core that delivers a total thickness of 45 mil (1.1 mm) when applied and requires no fixturing or curing time. Engineered to be strong, it can replace rivets, welds, and screws while providing faster production by eliminating the need for drilling, welding, grinding, and project cleanup. Offering seamless joining and minimal surface preparation, this easy-to-use bonding method keeps surfaces smooth and enhances the appearance of applications involving thin, lightweight, and dissimilar materials. Providing adhesion to a broad range of materials from metals, glass, and other high surface energy substrates, the advanced closed-cell acrylic technology provides secure bonding that protects against water and seals tightly for long-term durability. It performs in applications for short-term use (up to four hours) at a temperature up to 300 °F (149 °C) or long-term use withstanding up to 200 °F (93 °C). These attributes make 3M™ VHB™ Tape 4950 a reliable choice to take on a variety of bonding and sealing applications in transportation, signage, displays, general industrial, appliance, and electronics. Discover the many ways to apply the powerful bonding potential of 3M™ VHB™ Tape 4950.

Convenience Meets Extreme Bonding Power

Our 3M™ VHB™ Tape consists of a durable acrylic adhesive with viscoelastic properties. This provides an extraordinarily strong double sided foam tape that adheres to a broad range of high surface energy (HSE) substrates, including aluminum, stainless steel, galvanized steel, composites, acrylic, polycarbonate and painted or sealed wood and concrete. Our bonding tapes provide excellent shear strength, surface adhesion, durability and temperature resistance. Applications for this tape include stiffener bonding and panel and trim attachment.

Recommended Applications

- Decorative material and trim

- Nameplates and logos

- Panel to frame

- Stiffener to panel

Dream, Design, Deliver with the 4950 Family of 3M™ VHB™ TapesThe 4950 family of 3M™ VHB™ Tapes utilizes a general purpose adhesive on both sides of a firm type foam core. It is specifically designed for good adhesion to metals, glass and other high surface energy materials. They are commonly used in applications across a variety of markets including transportation, appliance, electronics, construction, sign and display and general industrial.

We invented 3M™ VHB™ Tapes in 1980 as the first of their kind. These unique tapes combine conformability with a strong, permanent bond. The result is a family of extraordinarily strong tapes that adhere to a broad range of substrates. 3M™ VHB™ Tape is a proven alternative to screws, rivets, welds and other forms of mechanical fasteners. Skyscrapers, cell phones, electronic highway signs, refrigerators, architectural windows and more all rely on this specialty bonding tape for one or more steps in the assembly, mounting, fastening and sealing process. This trusted and reliable tape offers a consistent bond, outstanding durability and excellent solvent and moisture resistance. 3M stands by all of its products and is there to provide you with design guidance and technical support when you need it.

Proven Reliability from 3M™ VHB™ Tapes

3M™ VHB™ Tape offers a durable bond in a way that mechanical fasteners can't. This tape enhances the appearance of finished goods by eliminating rivets and screws while providing immediate handling strength. In most cases, fastening with 3M™ VHB™ Tape is a quicker process than drilling, fastening, or using liquid adhesive. Our versatile line of tapes can be used indoors or outdoors in a variety of applications, including window, door and sign assembly, electronics, construction and countless other industrial applications. Chemically resistant as well as UV and temperature stable, 3M™ VHB™ Tape can withstand the heat of Dubai to the cold of Canada. The unique acrylic chemistry is extremely durable and resistant to change over time, making this a long-lasting and powerful tape you can trust.

Bringing Better Ideas to the Surface through Science and Innovation

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, our technologies help customers like you deliver competitive products to the market faster and more efficiently.

Details

Adhesive Type

Acrylic

Application

Bonding Glass to a Metal Oven Door, Exterior Side Panel Sealing, Roof Panel Bonding on Truck Cabs, Sealing, Trim & Molding Attachment, Wall & Door Panel Attachment

Backing (Carrier) Material

Acrylic Foam

Backing (Carrier) Thickness (Imperial)

3 mil

Brands

VHB™

Core Size (Imperial)

3 in

Foam Type

Firm

Indoor/Outdoor

Indoor/Outdoor

Industries

Appliance, Construction, General Industrial, Metalworking, Signage, Transportation

Liner Material

Densified Kraft Paper

Maximum Operating Temperature (Celsius)

149 ℃

Maximum Operating Temperature (Fahrenheit)

200 ℉

Product Color

White

Smallest Saleable Unit

Roll, Sheet

Units per Case

1.0,2.0,12.0,3.0,4.0,6.0,9.0,18.0

Dimensions and Classifications

Overall Length (Imperial)

11 in, 36 yd, 108 yd

Overall Length (Metric)

0.27 m, 32.9 m, 32.91 m, 32.92 m, 98.75 m, 98.76 m

Overall Width (Imperial)

0.375 in, 0.5 in, 0.75 in, 1 in, 1.5 in, 2 in, 3 in, 4 in, 8.5 in, 12 in

Overall Width (Metric)

9.525 mm, 12.7 mm, 19.05 mm, 25.4 mm, 38.1 mm, 50.8 mm, 76.2 mm, 101.6 mm, 215.9 mm, 304.8 mm