Fixing pipes? Duct tapes with strong adhesion are like magic for making quick and solid repairs.

Understanding Pipe Leaks and Temporary Solutions

Why duct tape is a go-to for emergency repairs

Duct tape is a household name when it comes to emergency repairs, and its popularity is no fluke. Its strong adhesive properties make it an excellent quick fix for pipe leaks, providing immediate relief in emergencies where speed is critical. The tape can effectively seal small to moderate leaks, which helps protect against water damage and can reduce potential repair costs. Furthermore, its versatility allows it to adhere to various pipe materials, including metal and plastic, ensuring broad applicability. This makes duct tape an essential item in any toolkit for unexpected plumbing issues.

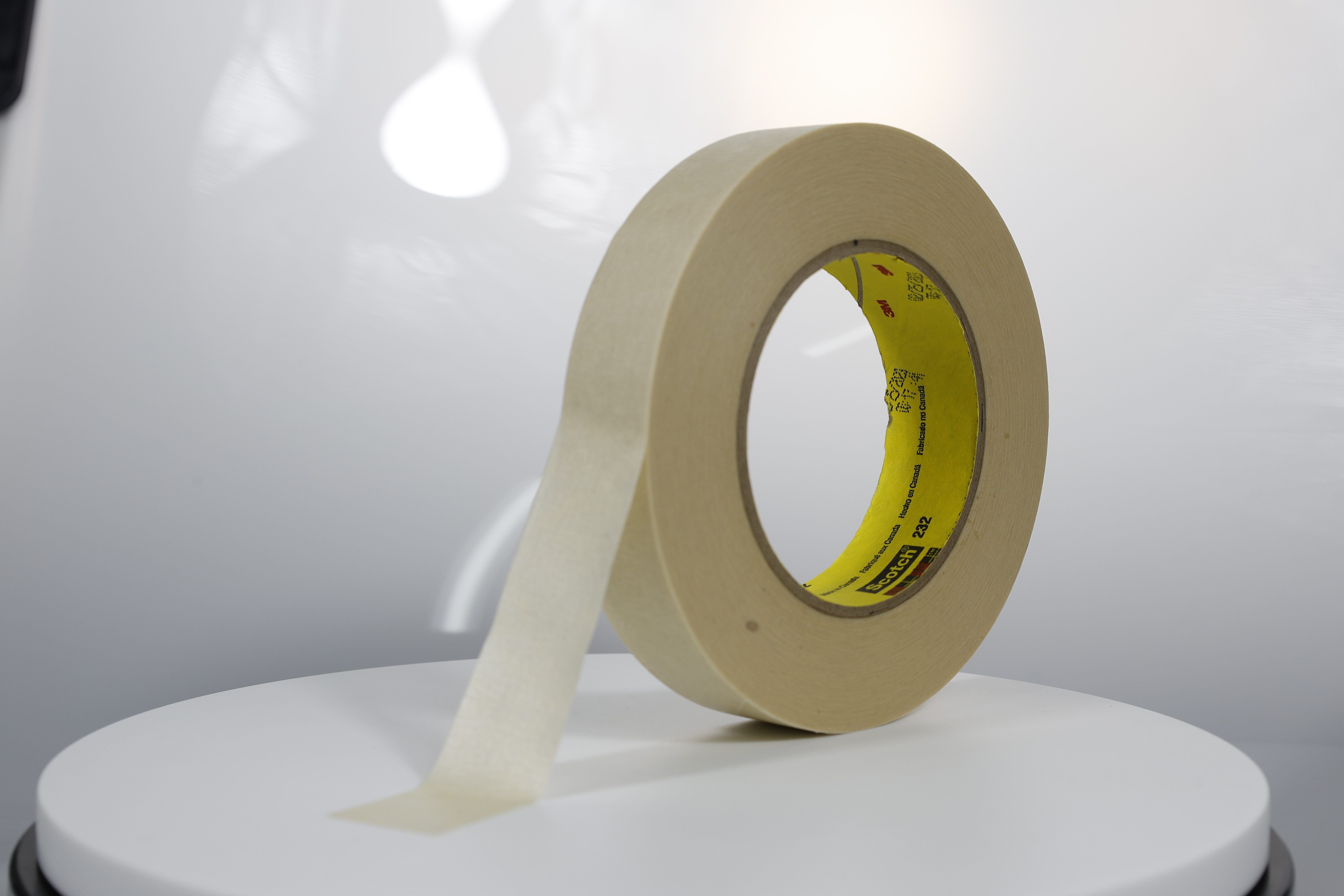

Limitations of masking tape and painters tape in plumbing

While duct tape stands out for quick emergency plumbing solutions, masking tape, and painters tape fall short in such applications. Masking tape lacks the adhesive strength necessary for long-lasting pipe repair, leading to leaks that often resume shortly after application. Similarly, painters tape is designed for clean removal and is ill-suited for wet conditions commonly found in plumbing situations, rendering it ineffective. Both types of tape deteriorate rapidly in high-moisture environments, making them unreliable for addressing piping emergencies, unlike duct tape or specialized repair tapes such as double-sided tape or rubber tape.

Key Features of Effective Duct Tape for Pipe Repairs

Adhesion Strength and Waterproof Capabilities

When selecting duct tape for pipe repairs, strong adhesion is crucial to ensure it bonds well with surfaces. This adhesive strength is vital whether the surface is wet or dry, providing a reliable temporary fix. Additionally, waterproof capabilities are essential to withstand leaking water without compromising the tape's integrity. Duct tape equipped with these features offers a robust solution when immediate action is needed to prevent further damage.

Durability Under Pressure: Rubber Tape vs. Standard Options

Rubber tape offers superior durability under high-pressure conditions, making it ideal for critical pipe repairs. Designed to withstand extreme pressures and temperatures, rubber tape is a preferred choice when standard duct tape falls short. While conventional duct tape can break down in these challenging environments, rubber tape's resilience ensures continued effectiveness, highlighting the importance of using specialized tape for robust repairs.

Flexibility for Uneven Surfaces (Double-Sided Tape Alternatives)

Flexibility is a key requirement in duct tape, especially when it comes to uneven surfaces. This adaptability helps achieve a watertight seal, crucial for effective pipe repairs. For complex situations, alternatives like double-sided tape can offer enhanced fitting in specific spaces, making them viable options for intricate repairs. The ability to conform to irregular surfaces ensures the tape effectively mitigates leaks across various applications.

Comparing Tape Types for Pipe Repairs

Duct Tape vs. insulating tape: When to Use Each

Duct tape and insulating tape serve different purposes in pipe repairs. Duct tape is ideal for temporary leaks because of its strong adhesive properties that help manage quick fixes. It adheres well to a variety of surfaces, making it a go-to option for many temporary repairs. However, when it comes to preventing electrical issues around pipes, insulating tape is the better choice. It is specifically designed to handle electrical insulation and can effectively protect against electrical hazards that may arise near plumbing systems. Choosing the right tape depends significantly on the nature of your repair needs, ensuring that you address the specific challenges involved.

Why Painters Tape Fails in Wet Environments

Painters tape is not suitable for plumbing repairs, particularly in wet environments. Designed for surface protection and painting tasks, it lacks the strong adhesive required for repairs involving water. When exposed to moisture, painters tape loses its grip, leading to ineffective repairs and the potential for further damage. This emphasizes the importance of selecting appropriate materials for plumbing repairs to avoid exacerbating the problem. In cases involving wet conditions, utilizing tapes like waterproof duct tape or rubber tape is essential, as these are specifically engineered to maintain adhesive properties in challenging environments.

Step-by-Step Guide to Applying Duct Tape for Pipe Leaks

Surface Preparation for Maximum Adhesion

Preparing the surface is crucial for ensuring duct tape adhesion. First, thoroughly clean the pipe surface to remove any debris or moisture. This preparation is integral in guaranteeing the duct tape sticks effectively and maintains enduring adhesion. For stainless steel or galvanized pipes, utilizing sandpaper to roughen the surface can enhance the tape's grip, creating a rough texture that boosts bonding capabilities.

Layering Techniques for Lasting Results

Applying duct tape effectively involves strategic layering techniques. Using multiple layers of duct tape can significantly enhance the seal's strength, particularly in areas susceptible to high pressure. Ensure each layer overlaps the previous one for optimal cohesion, with each overlay providing a protective barrier that prevents leaks and reinforces the sealing power of the tape.

Testing the Seal: Checking for Water Resistance

After applying duct tape, testing the seal is essential to confirm its effectiveness. Run water through the pipes and carefully observe for any signs of leaks or moisture escaping. If the duct tape remains intact without indicating water penetration, the application is likely successful, thereby ensuring pipe functionality and preventing potential damage from leaks.

When to Avoid Duct Tape and Consider Professional Help

High-pressure pipe scenarios requiring industrial solutions

Using duct tape in high-pressure pipe situations is risky and potentially disastrous. Duct tape, while versatile, is not designed for the extreme stresses exerted by high-pressure water flow, which can lead to catastrophic failures if used as a quick fix in such environments. It's essential to recognize that industrial-grade solutions are specially formulated to withstand these significant pressures, ensuring both safety and efficiency in managing high-stress scenarios. By opting for professional services, you can be assured of a more durable and appropriate repair that aligns with the specific technical requirements of high-pressure pipes.

Signs your leak needs more than temporary tape

Not every pipe leak can be adequately handled with duct tape. If you observe persistent dripping or notice significant water accumulation, it likely signals that a quick duct tape fix isn't enough. Such conditions suggest underlying issues that require more in-depth attention, such as cracks in pipes or damage to structural components. In these situations, it's prudent to consult a plumbing expert, as they can offer a comprehensive solution that addresses the root cause of the leak rather than just masking it temporarily. Consulting a professional can prevent future issues and safeguard against potential water damage.

Recommended Products

Hot News

Hot News

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01

-

Adhesive Tapes Market size is set to grow by USD 23.89 billion from 2024-2028, Increasing demand from end-user industries boost the market!

2024-08-22