In an industrial setting? High - strength duct tapes are essential for securing heavy stuff.

Understanding High-Strength Duct Tape in Industrial Applications

Key Properties of Industrial-Grade Duct Tape

High-strength duct tape is engineered to offer superior adhesive properties, making it a robust solution for various industrial applications. Its adhesive capabilities ensure a strong bond under stress, withstanding tensile forces and resisting abrasion. This characteristic is crucial for industries where reliability is paramount, such as automotive, construction, and heavy machinery maintenance. Furthermore, these tapes come with a durable backing material that resists tears and cuts, ensuring effectiveness in challenging environments. Unlike standard options, high-strength duct tapes maintain their integrity even when exposed to extreme temperatures, moisture, or chemicals, enhancing their usability in diverse sectors. This versatility underscores their essential role in industrial settings where performance cannot be compromised.

How High-Strength Tapes Differ from Standard Adhesives

High-strength duct tape distinguishes itself from standard adhesives through its advanced formulations that ensure exceptional grip and durability. Designed specifically to tackle demanding applications, these tapes outperform standard varieties by offering a cohesive bond that resists peeling and shearing forces. Unlike traditional adhesives that might provide only temporary fixes, high-strength duct tapes are built to handle heavier loads without losing their structural integrity. Research supports the superior performance of these tapes, noting their ability to endure greater strain and maintain effectiveness compared to conventional adhesive solutions. This makes them indispensable for industrial uses, where maintaining adhesion under stress is critical for operational success.

Critical Uses of High-Strength Duct Tape Across Industries

Heavy-Duty Bonding in Construction and HVAC Systems

High-strength duct tape plays a crucial role in the construction industry for its unparalleled heavy-duty bonding capabilities. It is specifically designed to secure insulation materials across a variety of surfaces, effectively preventing air leaks. This is essential in maintaining energy efficiency and ensuring adherence to building regulations. Additionally, in HVAC systems, this tape is adept at reinforcing duct connections. It offers superior resistance to external damages or moisture intrusion, protecting the integrity and performance of duct systems over time. Its robust adhesive properties make it a reliable choice in environments exposed to temperature fluctuations and humidity.

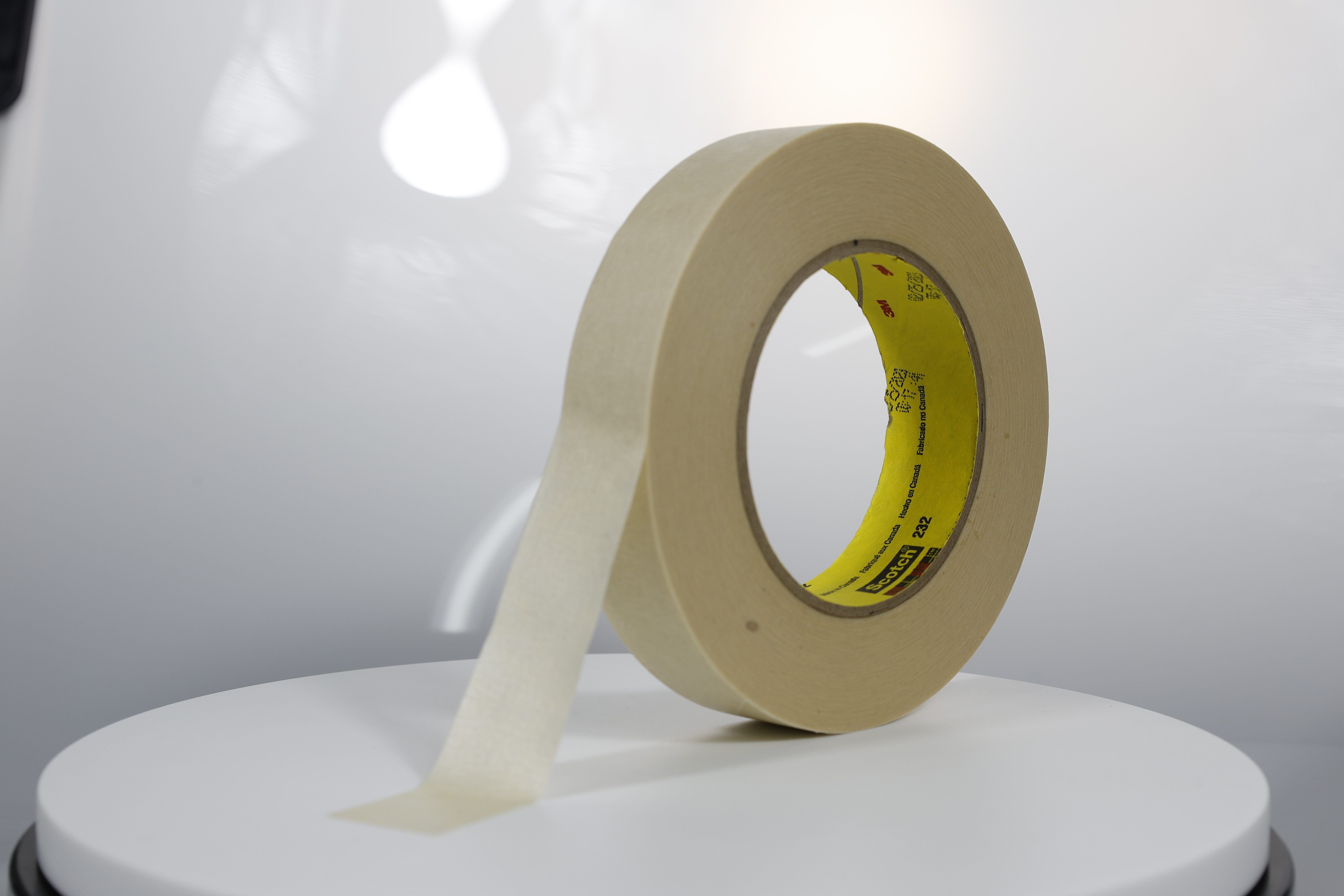

Automotive Masking Tape for Precision Paint Jobs

In automotive applications, high-strength duct tape is utilized as an automotive masking tape, essential for precision tasks such as painting. This tape ensures clean and sharp lines by effectively protecting surfaces from overspray, which is critical in achieving high-quality and aesthetically pleasing finishes. One of the key characteristics that make it a favorite in the automotive industry is its residue-free removal, which maintains the quality of the paintjob without leaving any unsightly marks. This property is particularly important in high-end automotive work where the preservation of surface quality is paramount.

Securing Cables and Equipment in Manufacturing

Manufacturers rely on high-strength duct tape for securing cables and equipment, which aids significantly in maintaining organization and safety. This tape is ideal for bundling cables, preventing them from becoming tripping hazards while ensuring neatness in industrial settings. Additionally, it supports transient setups, where equipment stability is required but also needs to be easily adjustable. The tape's multifunctional capacities make it an essential tool for secure and adaptable manufacturing practices. Its use ensures that temporary fixes and organizational needs are met with minimal disruption and maximum efficiency.

Choosing the Right Double-Sided Tape for Industrial Needs

Adhesive Strength vs. Surface Compatibility

When selecting double-sided tape for industrial applications, assessing adhesive strength is paramount. The tape must meet specific holding requirements depending on the materials being bonded—whether it involves lightweight plastics or heavier metals. Adhesive strength ensures that the tape can withstand varying loads and pressures, offering a reliable bond. Equally important is surface compatibility. The adhesive must effectively bond with diverse textures and finishes, such as smooth glass, textured metal, or rough concrete. Ensuring this compatibility leads to consistent performance and prevents failure during application, making it a crucial consideration in various industrial settings.

Weatherproofing and Temperature Resistance

Weatherproofing is an essential attribute for tapes used in outdoor settings. Industrial double-sided mounting tapes often need to resist moisture and UV rays effectively, ensuring their long-term durability in challenging environmental conditions. Moreover, temperature resistance is equally vital. These tapes should maintain their adhesive properties under temperature extremes, ranging from freezing cold to high heat, to avoid failures that could disrupt operations. Some industrial-grade tapes are specifically designed to withstand such conditions, ensuring that they function optimally regardless of the physical environment, thereby offering reliable performance in diverse industrial applications.

Top Features to Prioritize in Industrial Adhesive Tapes

Tensile Strength and Tear Resistance

When selecting an industrial adhesive tape, prioritizing high tensile strength is essential. This ensures that the tape can withstand significant stress and loads, which is crucial in industrial settings where robust bonding is required. A tape with high tensile strength maintains its integrity, preventing breakages that could compromise industrial processes. Equally important is tear resistance. This property prevents the tape from unwanted ripping during application, thus maintaining a secure and stable bond. Tear-resistant tapes are particularly beneficial in high-stress environments where the application process or external factors could cause typical tapes to fail.

Clear Double-Sided Mounting Tape for Discreet Applications

For applications where aesthetic value is paramount, clear double-sided mounting tape is indispensable. These tapes provide a strong, effective bond while remaining virtually invisible, making them ideal for environments where appearance cannot be compromised, such as retail displays and presentations. By offering discreet bonding solutions, clear double-sided tapes allow designers and business owners to focus on display without worrying about visible fasteners or adhesives. This feature is incredibly beneficial in creating seamless displays that enhance the overall aesthetic appeal of products and exhibits.

Reusability and Residue-Free Removal

Selecting adhesives that offer reusability can significantly cut down on costs and bolster sustainability across various industrial applications. These tapes not only save on material expenses but their reuse aligns with eco-friendly practices increasingly adopted by modern industries. Furthermore, residue-free removal is a critical feature, ensuring surfaces remain clean and uncontaminated post-removal. This is especially vital in environments like production lines and clean rooms, where maintaining cleanliness and avoiding contamination are top priorities. Using tapes that leave no residue also reduces cleanup time and effort, streamlining operational efficiency.

Future Trends in Industrial Adhesive Solutions

Innovations in Double-Sided Transfer Tape Technology

Double-sided transfer tape technology is witnessing significant innovations as emerging technologies enhance the adhesive capabilities to create stronger bonds and versatility. This advancement is crucial as industries demand high-performance adhesives that can cater to a variety of specific applications. These innovations are largely driven by investment in research and development. As funding in R&D increases, we can expect new formulations designed to serve niche applications across different sectors, from electronics to automotive industries. These innovations not only aim to improve performance but also offer solutions that are more adaptable to the changing needs of modern industries.

Sustainability in Tape Manufacturing

Sustainability in tape manufacturing is becoming increasingly important as demand grows for eco-friendly practices in industrial adhesive solutions. Manufacturers are now compelled to seek sustainable materials and adopt production processes that minimize environmental impact. This trend is expected to shape the future of adhesive products, focusing on reducing waste while maintaining performance standards. The push towards sustainability is also driven by stricter global regulations and heightened consumer awareness of environmental issues. As such, the industry is likely to continue innovating in biodegradable materials and energy-efficient manufacturing methods, ensuring that high performance aligns with sustainable practices.

Recommended Products

Hot News

Hot News

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01

-

Adhesive Tapes Market size is set to grow by USD 23.89 billion from 2024-2028, Increasing demand from end-user industries boost the market!

2024-08-22