Painting a car? You'll need high - quality masking tapes to get that professional finish.

Key Features of High-Quality Masking Tapes for Car Painting

Adhesion Strength for Crisp Paint Lines

Adhesion strength is critical in achieving clean, sharp paint lines when using masking tape for car painting. A strong adhesive ensures that paint does not seep under the tape, preventing uneven edges and maintaining crisp lines. High-quality masking tapes are designed with an optimal balance of tackiness, allowing them to stick firmly during the painting process while still being easy to remove without damaging the painted surface. Facts indicate that tapes with inadequate adhesion strength can cause issues such as paint bleeding and smudging, resulting in a subpar finish.

Temperature Resistance During Curing

Temperature resistance is crucial for masking tapes used in automotive painting, especially during the curing process. High-quality tapes must withstand elevated temperatures without deforming, ensuring that they remain effective under different environmental conditions. These tapes should perform well in both cold and hot situations, accommodating various painting techniques and environments. According to industry standards, automotive masking tapes should resist degradation up to 250°F (121°C) while retaining their adhesion properties.

Flexibility for Curved Surfaces

The flexibility of masking tapes is essential for conforming to various shapes, including curves and contours on vehicle surfaces. High-quality tapes often feature thin backing, which enhances their adaptability and ensures tight seals around intricate designs. Experts recommend using flexible tapes to achieve precise results when wrapping around complex shapes such as fenders and hoods. With flexibility, painters can easily navigate curved surfaces, ensuring the creation of sharp, clean lines that match the existing bodywork.

Residue-Free Removal Post-Painting

A significant benefit of high-quality masking tapes is their ability to be removed cleanly, leaving no adhesive residue behind. This feature is vital for maintaining the integrity of the paint job and preventing additional cleaning work after painting tasks are completed. Statistics show that users favor tapes offering residue-free performance as they often lead to fewer touch-ups post-removal, promoting efficiency and enhancing satisfaction with the final result.

Types of Automotive-Grade Masking Tapes

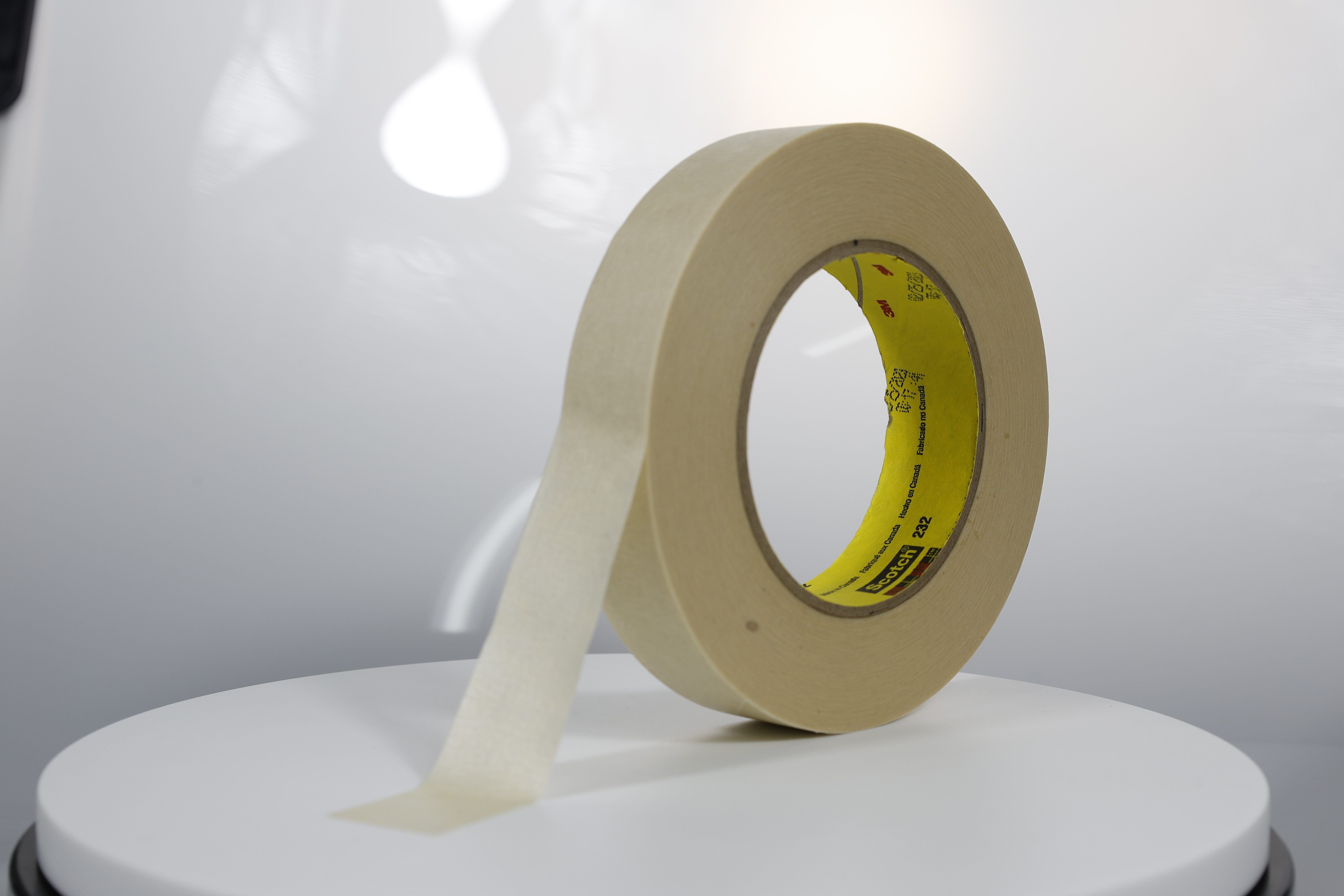

Painters Tape: Precision & Clean Edges

Painters tape is renowned for providing precision in automotive painting, enabling the creation of clean, sharp lines. With high adhesion technology, painters tape prevents paint from bleeding underneath, making it ideal for both professional and DIY projects. This ensures a seamless finish that reduces the need for time-consuming touch-ups. Industry data reveals that quality painters tape significantly cuts down on post-painting corrections, saving both time and effort for automotive specialists and hobbyists alike.

Double-Sided Tape for Complex Trim Work

Double-sided tape is crucial in securing complex trim parts during the repainting of vehicles. This type of tape maintains a strong bond without causing surface damage upon removal, ensuring a smooth process. Experts in automotive repair and customization endorse double-sided tape for its ability to enhance efficiency and precision in multi-part masking. Its secure adhesion makes it a reliable tool for holding intricate trim and molding in place during painting, allowing for flawless execution of design details.

High-Temperature Sealing Tape for Engine Bays

For tasks involving engine bays, high-temperature sealing tape is indispensable due to its resistance to extreme heat and moisture. Designed for high-exposure environments, this tape protects delicate components during the repainting process. Manufacturers advocate for the use of this sealing tape in extensive engine bay renovations or repairs, highlighting its robust performance in safeguarding critical parts. Its durability under such conditions ensures that it remains a vital tool for automotive technicians engaged in engine compartment work.

Fine Line Tape for Custom Designs

Fine line tape allows for detailed custom designs and precise color separations, making it a favorite among custom car painters. Its thinner profile prevents frayed edges and paint bleed, ensuring a clean, professional finish for detailed artwork. Many involved in custom car designs prefer fine line tape due to its reliability and ability to enhance visual appeal. This tape is particularly useful when creating intricate patterns or shapes, providing a solution for achieving the ultimate professional look in automotive artistry.

Application Techniques for Professional Results

Surface Preparation Best Practices

Proper surface preparation is vital to ensure that masking tapes adhere correctly and perform optimally. Thorough cleaning of surfaces to remove grease, dust, and other contaminants is a fundamental step to enhance tape adhesion. Studies show that well-prepared surfaces can improve adhesion strength by up to 50%, which leads to better overall painting results. By carefully preparing surfaces, you minimize the risk of tape failure and ensure a cleaner, more professional finish in your automotive projects.

Taping Curves and Body Contours

Mastering the technique of taping curves is crucial for achieving seamless transitions between paint colors and maintaining the integrity of design lines. Utilizing flexible masking tape is advantageous, as it allows easy navigation around body contours without causing creases or leaving gaps. Experts recommend a slow and steady approach when applying tape around curves to ensure even coverage and reduce the risk of paint bleeding, which ultimately enhances the quality of the paint job.

Layering Strategies for Multi-Stage Paint Jobs

Layering tape is essential in multi-stage paint jobs to manage colors and designs effectively. Applying different types of masking tapes at each painting stage can help achieve the desired finish. Professional painters frequently use a combination of masking tapes to enhance precision and flexibility in their application. These strategies are vital for complex designs, allowing for controlled layers and ensuring each stage of the paint job is executed with finesse and accuracy.

Avoiding Paint Bleed-Through

Preventing paint bleed-through is a critical challenge in automotive painting, requiring high-quality masking tape as a primary mitigation strategy. Proper adhesion and careful application are vital, especially in overlapping areas, to minimize bleed-through. Industry reports indicate that selecting the right tape for specific paint types can significantly reduce bleed-through. Therefore, it's essential to choose a masking tape that complements the paint type being used to ensure the best results.

Maintenance & Removal Considerations

Optimal Drying Times Before Tape Removal

Understanding the optimal drying times before removing masking tape is crucial to ensure the paint adheres properly and achieves a professional finish. Removing the tape too soon can cause the paint to peel off or create an uneven edge. Conversely, if you wait too long, the tape might become challenging to remove without disturbing the paint surface. To avoid these issues, it's essential to follow the manufacturer's guidelines on drying times, which typically consider the type of paint, environmental conditions, and specific tape used. This practice will ensure that the paint has secured maximum adherence before tape removal.

Safe Removal Methods to Preserve Paint

Employing safe removal methods is vital to safeguard the painted surface from damage during the tape removal process. Pulling the tape back at a 45-degree angle is a recommended technique, as it helps maintain the integrity of the paint's edge and reduces the risk of lifting. Research into best practices for tape removal suggests that this approach minimizes paint damage, thereby decreasing the need for touch-ups or repairs. Professionals emphasize the importance of applying consistent, gentle pressure during removal to preserve the quality of the paint.

Storage Tips to Maintain Tape Integrity

Ensuring proper storage of masking tapes is key to maintaining their performance and prolonging their shelf life. Tapes should be kept in a cool, dry environment to protect them from humidity and temperature changes, which can lead to deterioration. Regularly inspect tapes for signs of compromised quality, such as brittle edges or weakened adhesion, before using them. By following these storage tips, you can maintain the integrity and adhesive properties of the tapes, ensuring they perform effectively when needed.

Troubleshooting Adhesive Residue Issues

Adhesive residue can be a significant issue after a project, with many seeking effective solutions to this problem. Understanding how to troubleshoot and remove residue without damaging the underlying paint is essential. Utilizing adhesive removers or gentle solvents can often assist in eliminating residue efficiently. Surveys have shown that there is a growing interest in methods for resolving adhesive residue issues, highlighting the importance of this knowledge for anyone involved in painting and customization projects.

Recommended Products

Hot News

Hot News

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01

-

Adhesive Tapes Market size is set to grow by USD 23.89 billion from 2024-2028, Increasing demand from end-user industries boost the market!

2024-08-22