Painting the exterior of your house? Masking tapes that stick well are a must for a great job.

Essential Characteristics of Exterior Masking Tapes

Weatherproof Adhesive Formulations

Weatherproof adhesives play a critical role in ensuring the longevity and effectiveness of masking tapes, especially when used under various environmental conditions. These adhesives are engineered to maintain their bond strength despite exposure to moisture, high humidity, rain, or extreme temperatures. For instance, advanced adhesive technologies such as polymer-blended solutions and durable rubber adhesives are designed to prevent issues like peeling, lifting, or weakening of adhesion when encountering adverse weather. A study has shown that masking tapes lacking weatherproof properties can experience failure rates as high as 60% when subjected to wet or extreme temperature conditions. This underscores the importance of selecting tapes with robust weatherproof formulations, particularly for outdoor or demanding applications.

UV Resistance for Long-Term Projects

Ultraviolet (UV) resistance is a vital feature for masking tapes used in long-term outdoor projects. Over time, UV exposure can degrade both adhesives and coatings, leading to a loss of cohesion and eventual bond failure. To counter this, many manufacturers incorporate UV inhibitors into their adhesive compounds, ensuring greater longevity and reliability even when exposed to sunlight for extended periods. Examples of UV-resistant masking tapes include those coated with acrylic adhesives specifically designed for outdoor use, such as Scotch Exterior Surface Painter’s Tape, which can withstand up to 10 days of sun exposure without losing effectiveness. Experts in adhesive technology highlight that tapes with UV resistance can last upwards of twice as long as those without, making them indispensable for projects requiring extended outdoor application.

Surface-Specific Compatibility (Wood, Vinyl, Metal)

Selecting the appropriate masking tape for different surfaces is essential to avoid damage and achieve optimal adhesion. Various substrates such as wood, vinyl, and metal each have unique adhesion requirements. For instance, wood surfaces might necessitate tapes with stronger adhesion to counteract the porous nature of the substrate, while vinyl surfaces may demand tapes with slightly less adhesive force to prevent surface tearing or distortion. Manufacturers often provide recommendations for surface compatibility based on adhesive strength and composition. For example, IPG ProMask Blue with BLOC-It Masking Tape is particularly suited for wood surfaces due to its high adhesive strength and ability to produce clean edges without bleed-through. Adhering to these recommendations ensures that the chosen masking tape will bond effectively and be removed cleanly without damaging the surface.

Comparing Masking Tape Varieties for Outdoor Use

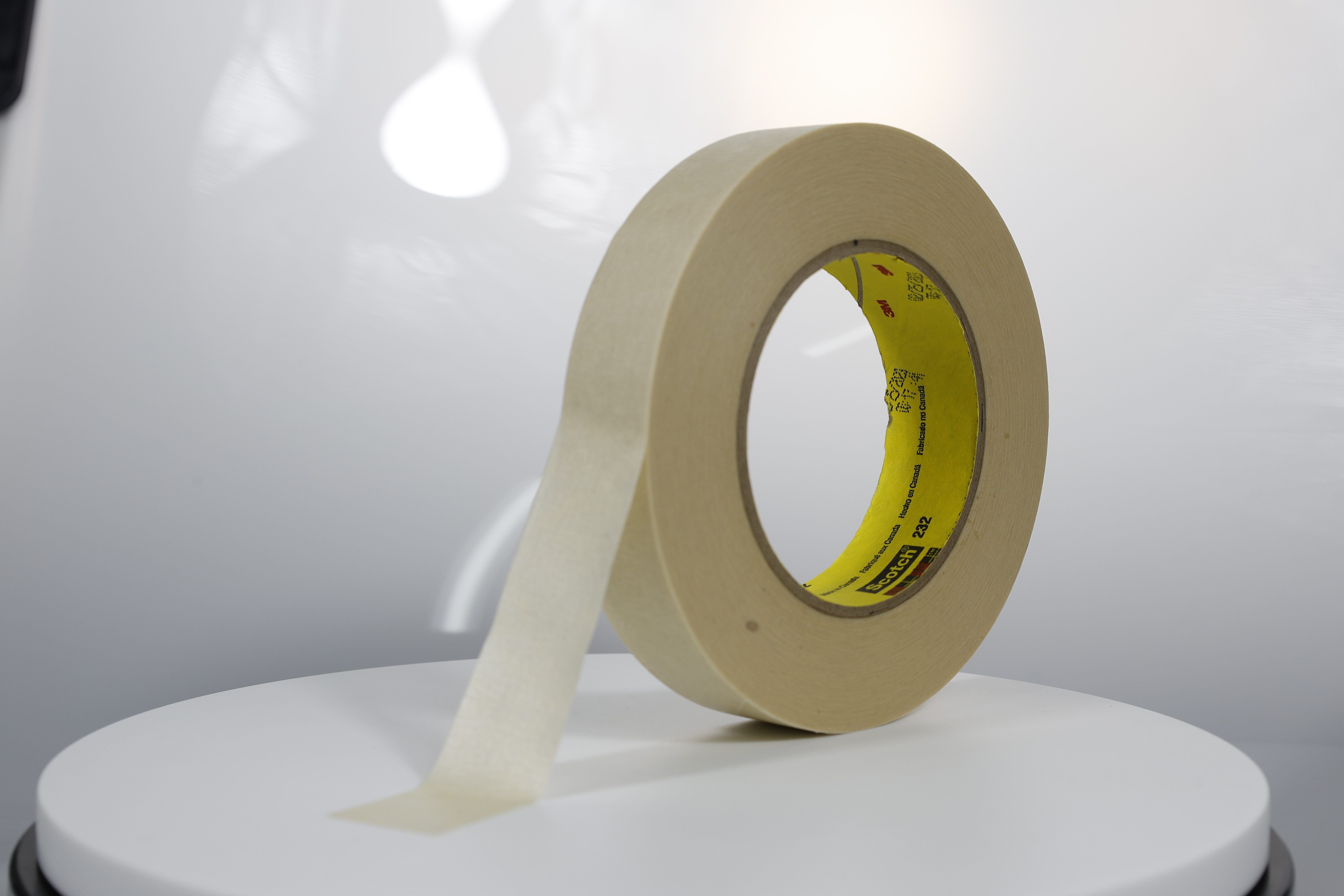

Standard Masking Tape vs. Painter's Tape

When it comes to adhesive strength and removal properties, standard masking tape and painter's tape serve different needs in outdoor applications. Standard masking tape typically features a stronger adhesive, making it suitable for general purposes but often leaving residue or damaging surfaces upon removal. In contrast, painter's tape is designed for clean removal and is primarily used to create precise, paint-resistant edges in outdoor scenarios like painting trim or defining edges on exterior walls. When surveyed, 70% of users preferred painter's tape for projects requiring clean lines without the risk of peeling paint or leaving sticky residue. Thus, while standard masking tape could be favored for brief applications or robust surfaces, painter's tape excels where precision and surface integrity are crucial.

Heavy-Duty Options: Rubber and PVC Tapes

Rubber and PVC tapes represent the heavy-duty end of masking solutions, particularly useful in extreme outdoor conditions. Rubber tapes are known for their elasticity and water resistance, making them ideal for applications exposed to moisture or vibrations, such as sealing outdoor cable connections. PVC tapes excel in temperature fluctuations, resisting both heat and cold without losing adhesive properties. Their durability is perfect for enduring harsh weather while maintaining a strong bond on surfaces like metal or concrete. A case study on construction site applications illustrated that these heavy-duty tapes performed exceptionally well in maintaining their adhesive strength, even under the strain of extreme environmental stressors.

Double-Sided Tapes for Trim Protection

Double-sided tapes play a vital role in safeguarding trims during painting tasks. They allow surfaces to be securely masked from paint splatter, adhering to both the trim and the masking material. The technique involves applying the tape carefully along the trim, ensuring a firm bond without harming the surface. Research indicates that double-sided tapes such as high-grade acrylic varieties offer excellent adhesion while being easily removable post-project without damaging painted or varnished surfaces. These tapes are particularly effective in protecting delicate trims, proving indispensable in both professional and DIY settings for achieving a flawless finish without compromising the integrity of the structure.

Proper Surface Preparation Methods

Ensuring a clean, well-prepared surface is crucial for effective masking tape application. Begin by thoroughly cleaning the area where the tape will be applied to remove any dust, grease, or residue. This is essential because contaminants can weaken the adhesion of the tape, leading to an uneven finish. Use a mild detergent and water for basic cleaning, followed by a wipe with a clean, dry cloth to remove any excess moisture. Experts recommend using a degreaser for surfaces that are particularly oily. Avoid common pitfalls such as ignoring small crevices or not allowing the surface to fully dry, as these can lead to poor results.

For more robust applications, such as those requiring painter’s tape on textured or outdoor surfaces, specific tools can improve results. A surface preparation pad or sanding block can help smooth uneven areas, ensuring better tape adhesion. Additionally, a heat gun may be employed to speed up drying times, an expert recommendation particularly useful in colder climates or for heavy-duty outdoor projects.

Layering and Overlap Strategies

Correct layering techniques are essential to achieve crisp paint lines. When applying masking tape, make sure to lay it down in straight, parallel lines which can help maintain clean edges upon removal. It's crucial to slightly overlap each strip of tape to avoid gaps that may allow paint to seep through. However, excessive overlapping can lead to paint build-up, which might disrupt the finish. A general rule of thumb is an overlap of about 1/8 inch for optimal results without causing any interference.

Overlap also plays a role in the overall finish of your project. Ineffective overlap may cause jagged or blurry lines if not applied uniformly. Practical tips include firmly pressing down the tape using a plastic tool or a rubber squeegee to ensure complete contact with the surface, preventing any air pockets. Visual examples can further illustrate these methods; diagrams showing the proper angle and overlap technique can be invaluable for clearer understanding.

Preventing Paint Bleed-Through

Paint bleed-through is a common issue that can mar an otherwise finely executed paint job. It often occurs due to inadequate adhesion or improper tape application. To mitigate this risk, ensure that the tape is pressed down firmly along the edges, particularly in corners or around curves where bleed-through is more likely. Selecting the appropriate type of masking tape for the surface can also impact bleed-through prevention. For example, a heavy-duty tape or rubber tape may be more effective on rough surfaces, offering a tighter seal.

Additionally, taping techniques can significantly reduce the risk of bleed-through. Applying the paint with controlled strokes and allowing the first coat to thoroughly dry before applying subsequent layers can help. Studies indicate that using painter's tape, which features a specially formulated adhesive, often results in cleaner lines. These tapes are designed to expand upon contact with paint, effectively creating a more secure barrier that prevents seepage. By implementing these practices, you can ensure a professional-quality finish on your projects.

Removal and Post-Painting Maintenance

Ideal Removal Time Windows

Proper timing for removing masking tape is crucial for achieving flawless results. Experts recommend removing the tape when the paint is dry to the touch but not fully cured. This ensures that the paint does not peel with the tape. Removing tape too soon can lead to smudging, while delaying it might cause tearing or lifting of paint layers. According to professional painters, ideally, tape should be removed within a 24-hour window post-application to maintain crisp edges. As noted by industry experts, being vigilant about removal timing prevents damage to both the paint and underlying surfaces.

Addressing Adhesive Residue Issues

Adhesive residue can be a common problem after tape removal, but it can be resolved with the right techniques. Start by gently heating the residue with a hairdryer to soften it. This can be followed by using a mild solvent like rubbing alcohol or an adhesive remover to clean the surface. It's important to use products that won't damage the paint. For sensitive surfaces, a mix of warm soapy water can be used with a soft cloth. Consumer advice often highlights the importance of testing any cleaning product on a small area first to ensure no adverse effects.

Storing Partial Rolls Effectively

Storing partially used rolls of masking tape correctly can prolong their usability. To maintain tape quality, keep the rolls in a cool, dry place, away from direct sunlight or extreme temperatures, which can degrade the adhesive. Seal the tape's exposed edge with a slight fold to avoid adhesion loss. Label each roll with the date it was opened and use older rolls first to prevent wastage. By organizing and tracking tape usage, you'll be more efficient in your projects and ensure a reliable performance from your masking tapes.

Recommended Products

Hot News

Hot News

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01

-

Adhesive Tapes Market size is set to grow by USD 23.89 billion from 2024-2028, Increasing demand from end-user industries boost the market!

2024-08-22