Tired of replacing electrical tape outdoors? Try an UV - resistant one and save money!

Understanding UV Resistant Electrical Tape

The Science Behind UV Resistance

UV resistance is a critical characteristic for electrical tapes used in outdoor applications. UV resistant electrical tapes are designed to withstand prolonged exposure to ultraviolet radiation from the sun, preventing degradation and maintaining their insulating properties. These tapes often incorporate additives like stabilizers in their chemical composition, which protect them against UV-induced damage. Studies indicate that UV resistant electrical tapes can last significantly longer in outdoor environments compared to standard tapes. These tapes continue to perform effectively in harsh conditions, maintaining their adhesion and insulation for years, which makes them ideal for industries such as construction and automotive. According to market research, the longevity and durability of UV resistant tapes contribute to their increasing demand globally.

insulating tape vs. Standard Electrical Tape

When comparing insulating tape to standard electrical tape, the former offers superior insulation and protection against heat and UV rays. Insulating tapes are specifically designed for environments where higher temperatures and UV exposure are common. This makes them preferable in scenarios where electrical connections are exposed to direct sunlight or heat-emitting equipment. On the other hand, standard electrical tapes may fail under such conditions, leading to potential hazards like short circuits or insulation breakdown. Experts suggest using insulating tapes for outdoor and industrial applications, where environmental factors can compromise the safety and functionality of electrical systems.

Rubber Tape vs. PVC Tape: Material Comparisons

Rubber tape and PVC tape each offer distinct properties making them suitable for varied outdoor uses. Rubber tape is renowned for its exceptional flexibility and insulation capabilities, also providing an excellent barrier against moisture. Conversely, PVC tape is highly valued for its UV resistance and durability. For outdoor conditions, rubber tape is often utilized in scenarios where flexibility and moisture sealing are paramount, such as in automotive and marine settings. On the other hand, PVC tape is widely recommended for applications requiring exposure to sunlight and harsh weather conditions. Professionals typically recommend PVC tape for construction and electrical insulation in sunny environments, while rubber tape is favored in moist or damp areas.

Key Features of Long-Lasting Outdoor Tapes

Weatherproofing and Temperature Tolerance

Weatherproofing is a critical feature of outdoor tapes, ensuring the protection of electrical systems against varying climatic conditions, including extreme temperatures. High-quality UV resistant tapes are designed to endure temperature fluctuations, maintaining their integrity and performance over time. According to studies and manufacturer data, these tapes can withstand temperatures ranging from freezing cold to intense heat, proving their resilience. The importance of weatherproofing cannot be overstated, as it significantly reduces maintenance costs by preventing environmental damage, making them a cost-effective choice for long-term outdoor installations.

Adhesive Strength in Harsh Conditions

Adhesive strength is vital for outdoor tapes, as it ensures bond integrity when exposed to harsh elements like rain, wind, and UV radiation. UV resistant tapes are tested under rigorous conditions to prove their performance. Their adhesive holds up even when subjected to challenging environments, preventing failures in electrical connections. Instances where inadequate adhesive strength led to costly repairs and compromised installation highlight the necessity of using robust tapes in outdoor applications, making adhesive strength an essential consideration for project reliability.

Double-Sided Applications for Versatility

Double-sided adhesive tape offers remarkable functionality and benefits for various outdoor installations. It is versatile, making it ideal for projects that require mounting or securing objects firmly without visible tape. Applications include securing solar panels, attaching signs, and mounting outdoor equipment. User testimonials and professional insights attest to its effectiveness, emphasizing its role in enhancing project versatility. Double-sided tape is a practical choice for outdoor tasks where both stability and aesthetics are required, underlining its value in diverse applications.

Securing Wire Tape in Electrical Systems

UV-resistant wire tape plays a crucial role in securing electrical systems by protecting them from environmental exposure and potential damage. Outdoor electrical systems are particularly vulnerable to weather conditions, which can lead to failures if not adequately protected. Statistics reveal that improper taping methods contribute to up to 30% of electrical system failures in outdoor environments, highlighting the importance of using reliable tapes. For optimal performance, it is essential to follow best practices when installing wire tape. Ensure that the tape is applied tightly around joints and connections without gaps. Clean and dry the application surface to maximize adhesion, and use multiple layers if the conditions are particularly harsh or if additional insulation is needed. These practices will help ensure the longevity and reliability of outdoor electrical installations.

Sealing Outdoor Fixtures with Rubber Tape

Rubber tape is an effective solution for sealing outdoor fixtures due to its excellent waterproofing capabilities. This type of tape is ideal for creating watertight seals on outdoor lights, junction boxes, and other fixtures exposed to moisture. Common applications requiring robust sealing involve protecting these fixtures from water ingress, which can cause electrical malfunctions or corrode metal parts. Experts recommend ensuring the surfaces are clean and dry before applying rubber tape to maximize its effectiveness. Furthermore, overlapping the tape on itself during application can enhance its waterproofing capability. By following these expert recommendations, you can ensure secure sealing, safeguarding outdoor electrical fixtures from the elements.

PVC Tape for Industrial and Residential Use

PVC tape offers remarkable versatility for both industrial and residential applications. It is widely used in insulation and marking due to its strength and flexibility. Compared to other materials, PVC tape is a cost-effective choice for projects requiring an affordable yet durable solution. When selecting the right tape for specific use cases, consider the environment and exposure conditions. For industrial settings, opt for high-temperature-resistant variants to ensure long-term performance. In residential applications, standard PVC tape works well for general electrical insulation tasks. By choosing the appropriate type of PVC tape for each application, you can achieve a balance between performance and cost-effectiveness, making it an ideal choice for various environments.

Choosing the Right UV Resistant Tape for Your Project

Assessing Environmental Exposure

Choosing the right UV-resistant tape for outdoor projects necessitates a thorough assessment of environmental exposure. Evaluating key factors such as sunlight intensity, temperature fluctuations, humidity levels, and potential exposure to chemicals or pollutants is crucial in selecting the optimal tape. For instance, areas with high UV exposure may require specialized insulating tape designed to withstand prolonged sun exposure. Industry reports suggest that ambient conditions can significantly impact tape performance, leading to reduced adhesion and lifespan. Understanding these environmental conditions ensures that the tape selected will maintain its integrity and effectiveness throughout its lifespan.

Balancing Flexibility and Durability

An important aspect to consider when selecting UV-resistant tapes for outdoor projects is balancing flexibility and durability. While flexible tapes are essential for adapting to various surfaces and shapes, durability ensures the tape's long-lasting protection against external elements. Case studies, such as those conducted by construction firms, demonstrate that choosing the wrong balance can lead to premature wear, affecting project outcomes and leading to costly repairs. Insights from engineers caution against overlooking either aspect and recommend assessing specific project demands to make informed decisions regarding tape attributes.

Industry Standards and Certifications

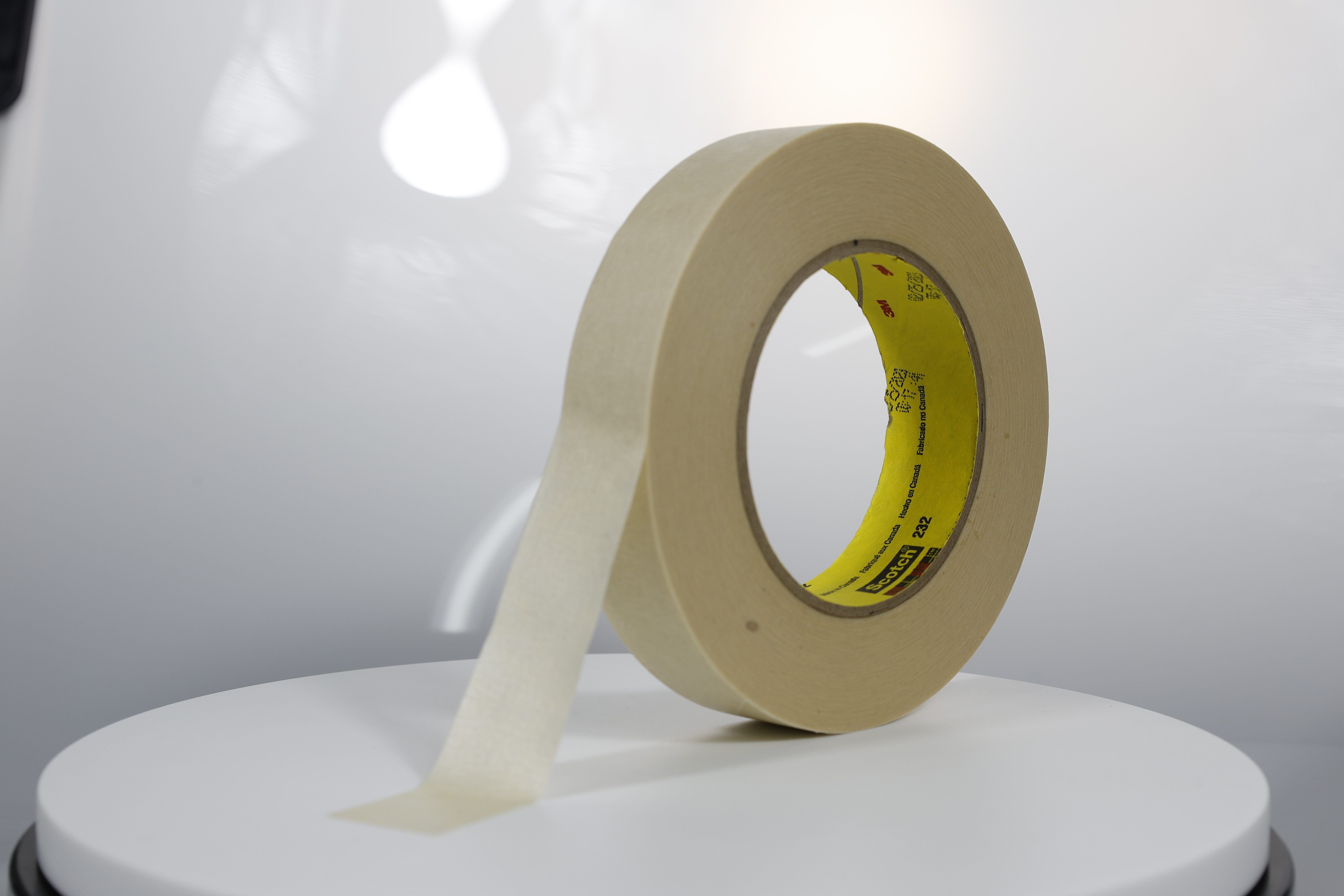

Understanding industry standards and certifications is vital when selecting UV-resistant electrical tape for outdoor applications. These standards ensure the tape meets specified performance and safety criteria, providing reliability in demanding conditions. Compliance with certifications like UL, ASTM, and ISO is essential for maintaining safety and effectiveness. Leading manufacturers in the tape industry, such as 3M and Tesa, consistently meet or exceed these standards, offering products that guarantee optimal protection and reliability in outdoor environments. Recognizing these certifications guides consumers in choosing products that align with industry benchmarks.

Recommended Products

Hot News

Hot News

-

TAPE Team Conquers Shenzhen’s Phoenix Mountain: Unity, Ambition, And New Heights In 2025

2025-02-21

-

The Role of Polyimide Electrical Tape in Electronics Insulation

2025-01-21

-

High Strength Double-sided Tape for Secure Bonding

2025-01-15

-

Durable Foam Tape for High-Performance Applications

2025-01-10

-

High Temperature Resistant Masking Protective Tape for Extreme Conditions

2025-01-01

-

Adhesive Tapes Market size is set to grow by USD 23.89 billion from 2024-2028, Increasing demand from end-user industries boost the market!

2024-08-22